POWER & ENVIRONMENTAL FIELD 유원만의 국내 유일 파트너 컴퍼니가 세계 정상급 기술력으로 제작한 환경분야 선진 기술을 소개합니다.

Acoustic Cleaner (ACS)

NOx Reduction Technology (CCA)

Boiler Diagnostic System (VALMET)

SCR Catalyst & Services (CORMETECH)

-

General Function

- 보일러 탈질 설비(SCR Reactor) 의 표면에 Ash가 쌓이거나 달라 붙는 것을 방지하는 제품 - 음파를 이용하여 엷은 공간과 접근이 어려운 부분에도 효과적으로 Scale을 제거 및 방지할 수 있고 기계적인 충격 없음 - 원가절감, 생산성 증대 및 원활한 장비 운전을 위한 Cleaning System

ADVANTAGES

- Low Initial Investment - Easy Installation - Low Installation Cost - Low Maintenance Cost - Low Operational Cost - No Structural Damage - No Mechanical Wear on Equipment Surfaces - No Corrosion or Blockage - Cleaning of Inaccessible Parts - Continuous Plant Operation - Design & Installation Expertise from the ACS Professional

| APPLICATIONS: | |

|---|---|

| Boilers | Prevents particulate deposit build-up and increases heat transfer efficiency |

| Precipitators |

Prevents: - Distribution plate plugging - Collecting plate build-up - Electrode build-up - Hopper pluggage - Complete elimination of tumbling hammer rapping systems |

| Selective Catalytic Reduction (SCR) | Prevents deposit build-up on catalyst modules |

| Economizers | Prevents deposit build up on boiler tubes |

| Baghouses |

Prevents: - Short bag life - High pressure drop - Hopper pluggage |

| Hoppers / Silos |

Prevents: - Plugging - Material flow problems such as bridging and ratholing - Deposit build-up |

| Ductwork / Breeching |

Prevents: - Excessive fallout - Deposit build-up |

| Fans | Prevents out of balance conditions |

| Air Pre-Heaters | Prevents particulate deposit build-up and increases heat transfer efficiency |

| Acoustic Cleaner Lineup | ||

|---|---|---|

Magnum Magnum |

Output Power : Weight : Air Requirements : |

142 db 119 lbs. 63” Pressure - 90 PSI Consumption - 73 SCFM |

Magnum C Magnum C |

Output Power : Weight : Air Requirements : |

142 db 129 lbs. Pressure - 90 PSI Consumption - 73 SCFM |

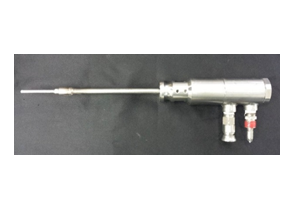

Model AC-230 Model AC-230 |

Output Power : Weight : Air Requirements : |

150 db 56.5-59 lbs. 26.75” Pressure – 70-90 PSI Consumption – 70-80 SCFM |

Model AC-220 Model AC-220 |

Output Power : Weight : Air Requirements : |

150 db 36.5-38.5 lbs. 16.5” Pressure – 70-90 PSI Consumption – 70-80 SCFM |

POWER & ENVIRONMENTAL FIELD 유원만의 국내 유일 파트너 컴퍼니가 세계 정상급 기술력으로 제작한 환경분야 선진 기술을 소개합니다.

Acoustic Cleaner (ACS)

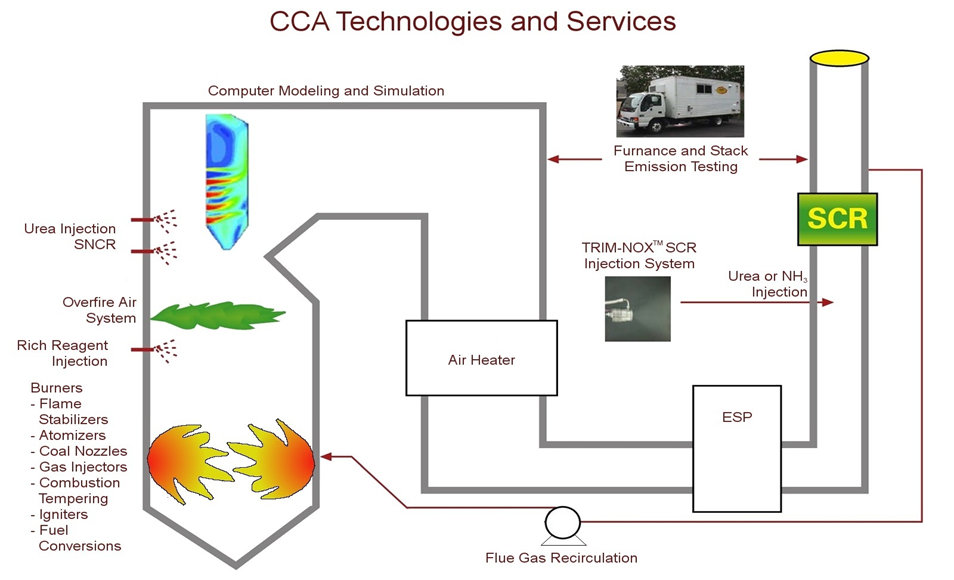

NOx Reduction Technology (CCA)

Boiler Diagnostic System (VALMET)

SCR Catalyst & Services (CORMETECH)

-

General Function

- 보일러 화로(Furnace) 내에 장착되어 있는 Burner를 교체 혹은 개조 하여 NOx를 저감 및 보일러 연소 효율을 향상 시키는 기술 - Burner 뿐만 아니라 NOx 저감에 도움을 주는 기술을 보유 (OFA, FGR, SNCR, SCR, RRI, CT 등) - 경쟁사 대비 NOx 저감 능력이 뛰어나며 Customizing 설계로 보일러 연소 효율이 우수함 -

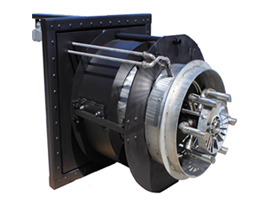

Burners & Combustion Systems

Applications:

- Utility Power Boilers – Wall-fired, T-fired - Package Boilers - Recovery Boilers – Startup & Aux Fuel Burners

Burner Heat Input Capacities:

- 25 MMBtu/hr to 300+ MMBtu/hr

Fuels: Any combustible gaseous or liquid fuel

- Natural gas, Refinery gases, Propane, Hydrogen, Landfill / Digester gases - Process Off Gases and Liquids - Hazardous Waste Gases and Liquids - Heavy Fuel Oil - Ultra Heavy Fuel Oils (Pitch/Bitumen) - Light Fuel Oils, Kerosene - Biomass (wood, nut shells, etc.)

Low NOx Systems

- Multi-Fuel Burners firing liquids & gases up to 5 fuels per burner - Overfire Air - FGR - H2O Injection

Performance Upgrades

- Flame Stability Improvement - CO/Carbon Loss Reduction - Reliability improvements - Life Extension

-

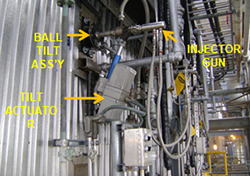

BSelective Non-Catalytic Reduction (SNCR) Systems

SNCR System Design

- Injection of Urea or Ammonia (mixed with air and water) into Furnace Section of Field Erected Boilers - NOx Reduction Reaction Temperature Window: 900 – 1,150 C - Optimum Injector Locations determined by CFD Modeling of Furnace and Exhaust Gas Profiles - Typical NOx reduction of 35%-65% - CCA Developed Unique Tilting Injector Design to Improve Efficiency and Reduce Equipment Costs -

Selective Catalytic Reduction (SCR) System

SCR System Design

- CCA Developed and Implemented Unique, Patented Direct Injection SCR process on Engines, Boilers and Turbines ┕ Reduces capital and operation costs by as much as 60% - NOx Reduction Reaction Temperature Window: 175 – 482 C - Optimum Injector Locations determined by CFD Modeling of Furnace and Exhaust Gas Profiles - Typical NOx reduction of 75%-95% - CCA Specializes in Urea based SCR ┕ Urea is a safer alternative to ammonia as an SCR reagent

Injection Distribution Module

Injection Distribution Module

Reagent Storage Tank

Reagent Storage Tank

Urea or Ammonia Pump Skid

Urea or Ammonia Pump Skid

SNCR Injectors

SNCR Injectors

Reactor Box w/ Catalyst

Reactor Box w/ Catalyst

Ammonia / Urea Injector

Ammonia / Urea Injector

Modular Injection Skid

Modular Injection Skid

Reagent Storage Tank

Reagent Storage Tank

POWER & ENVIRONMENTAL FIELD 유원만의 국내 유일 파트너 컴퍼니가 세계 정상급 기술력으로 제작한 환경분야 선진 기술을 소개합니다.

Acoustic Cleaner (ACS)

NOx Reduction Technology (CCA)

Boiler Diagnostic System (VALMET)

SCR Catalyst & Services (CORMETECH)

-

General Function

- IR Camera (보일러 이미징 시스템) 고정식 타입 - IR Camera (보일러 이미징 시스템) 휴대용 타입 - Acoustic Pyrometer (보일러 노내 온도 분포 측정 시스템)

POWER & ENVIRONMENTAL FIELD 유원만의 국내 유일 파트너 컴퍼니가 세계 정상급 기술력으로 제작한 환경분야 선진 기술을 소개합니다.

Acoustic Cleaner (ACS)

NOx Reduction Technology (CCA)

Boiler Diagnostic System (VALMET)

SCR Catalyst & Services (CORMETECH)

-

General Function

- SCR Catalyst for Coal, Oil, and Gas - DUSTBUSTER SCR Catalyst - SCR Catalyst Regeneration - SCR Catalyst Management Service - SField Services Support